Advanced NDT Management

Advanced NDT Management

Identify hidden defects before they cause critical failures with advanced AI-driven NDT. Receive instant defect classification, predictive failure alerts, and automated compliance reporting. Achieve 99.9% detection accuracy and accelerate analysis by 70%—preventing disasters before they occur.

Complete NDT Management

Tools and workflows designed for precise, efficient, and reliable non-destructive testing operations.

Multi-Method NDT

Data Management

Automated Reporting

Quality Assurance

Trend Analysis

Technician Management

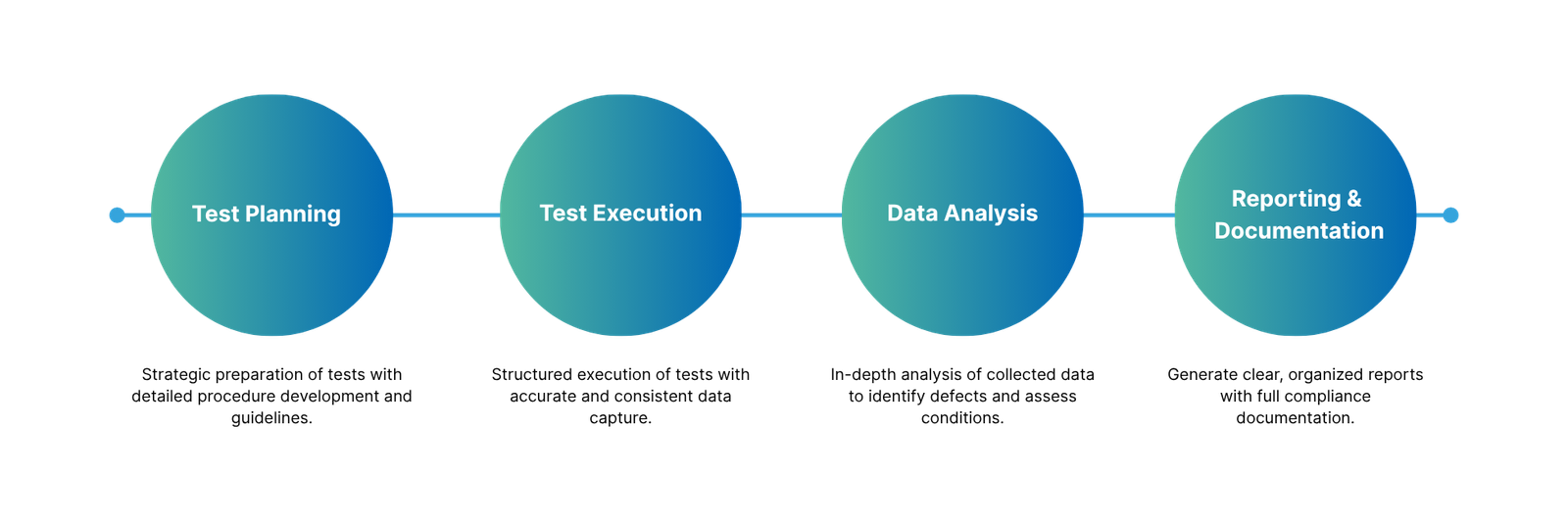

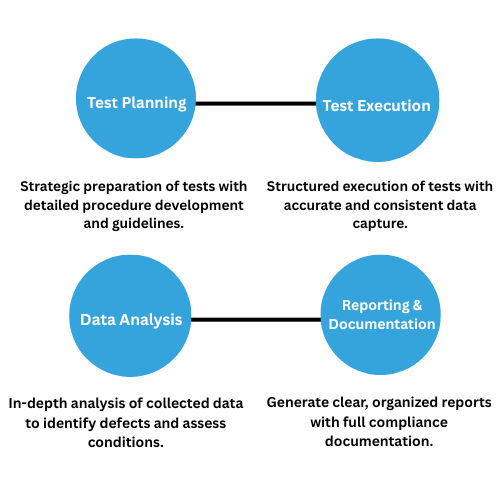

NDT Testing Lifecycle

End-to-end management of every phase in the non-destructive testing process for maximum efficiency and accuracy.

Proven Excellence

Delivering trusted performance gains in every inspection.

High Accuracy

Enhance NDT accuracy by up to 90%.

Faster Testing

Cut testing durations in half.

Efficient Reporting

Reduce reporting effort by 75%.

Full Compliance

Guarantee compliance every time.

Technician Productivity

Boost technician efficiency by 35%.

Reduced Rework

Minimize rework by 80%.

Supported NDT Techniques

Full coverage of major non-destructive testing methods.

The NDT AI Assistant

Pioneering the future of NDT automation, our AI-powered assistant streamlines and enhances inspection workflows with intelligent analysis and interpretation.

Unified Data Ingestion

Consolidates inspection data from UT, PAUT, AUT, MFL, RT, LPT, and MPT into one integrated platform.

AI-Powered Interpretation

Uses deep learning to detect, size, and classify flaws, cutting analysis time while boosting accuracy.

Historical Data Comparison

Aligns new scans with past results to track defect growth and guide RBI planning.

Defect Risk Assessment

Classifies defects per ASME codes and risk matrices, prioritizing issues for engineering review.

Rope Access Integration

Enables detailed QA/QC for rope inspections, validating technician input against AI insights.

Smart Reporting Engine

Generates automated reports with defect summaries, compliance checks, and actionable recommendations.

FAQ (Frequently Ask Questions)

UT, RT, MT, PT, ET, and VT are supported with a common data model and consistent review/reporting workflows.

Yes. AI-assisted analysis accelerates detection, classification, and sizing to reduce interpretation time.

Yes. It supports ASNT/ISO practices, and report templates can be tailored to your requirements.

Technicians upload from field devices; the platform ingests common NDT formats and DICONDE-like files.

Yes. Historical trending tracks progression to support RBI planning and targeted re‑inspection.

Auto-generated PDF/Excel include findings, annotated images, reviewer notes, signatures, and logs.

Benchmarked programs report 99%+ assisted detection, contingent on data quality and method.

Comprehensive audit trails capture scan lineage, reviewers, changes, timestamps, and approvals.

Yes. Field capture and review work offline with secure synchronization when connectivity returns.

Encryption in transit/at rest, RBAC, and tamper‑evident logs protect sensitive inspection data.